ERP Production

You would like to easily plan your industrial production company and always have the overview of the current status of production? Our hardware and software solution is perfectly adapted to these requests.

- Transparent: thanks to graphical presentation of past and future

- Proactive: material requirements on the basis of production forecasts

- Integrated: from purchasing of material to sales

- Transparent: the proposal board shows needs of raw material and production

- Proven: in over 200 companies around the world

Your benefit of ERP Production

Clear guidelines for production, as well as complete recording of events during production, are the basis for cost analyzing and optimization of production processes. The tracing of produced goods back to the raw materials used and extraordinary incidents during production help to assure and document quality and to train your staff specifically.

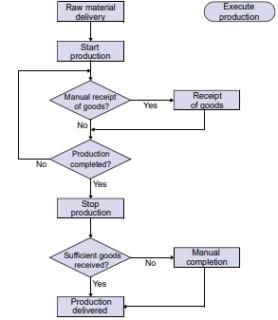

Production order

- One or more order positions, all of the same article but for different linked orders.

- A work plan which defines the process steps to produce the order.

- A parts list which contains the raw material that is needed at the different process steps.

- Production forecast based on the detail planning, the shift plan and the current machine efficiency.

- Raw material requirements based on the production forecast.

Production machines

ERP Production is suitable for endless, flat and piece production, as well as for processing of batches (eg. in a washing machine) or filling and packaging.

We connect your production machines via our own hardware and the industrial network. Production progress and automatical down times will be recorded in real time.

User interactions

Activities and user entries are systematically recorded and protocolled and are available as additional evaluations.

Proposal board

The proposal board shows all needs and allows the planner to create production orders with just a few clicks. Same articles of different (sales) orders can be combined to one production order.

With the available machine capacities you can determine the work plan for the production order.

With the same tool you can manage the purchasing of raw materials for your production orders.

Reporting

- Order reports for planning, tracing and analyzing

- Material reports for warehouse and tracing

- Shift reports for machine optimization and long-term evaluations

- Detailed machine events and user activities