Inspection / Laboratory Planning

The efficient software solution for inspecting the greige and finished fabrics at the inspection table.

Online / offline quality management for the early detection of manufacturing defects.

- Innovative: producing quality instead of controlling thanks to the graphical tracing that is unique in its class

- Optimized: inspector operations reduced to a minimum

- Efficient: evaluating according to the proven approaches in weaving and knitting

Most Suited to Your Needs

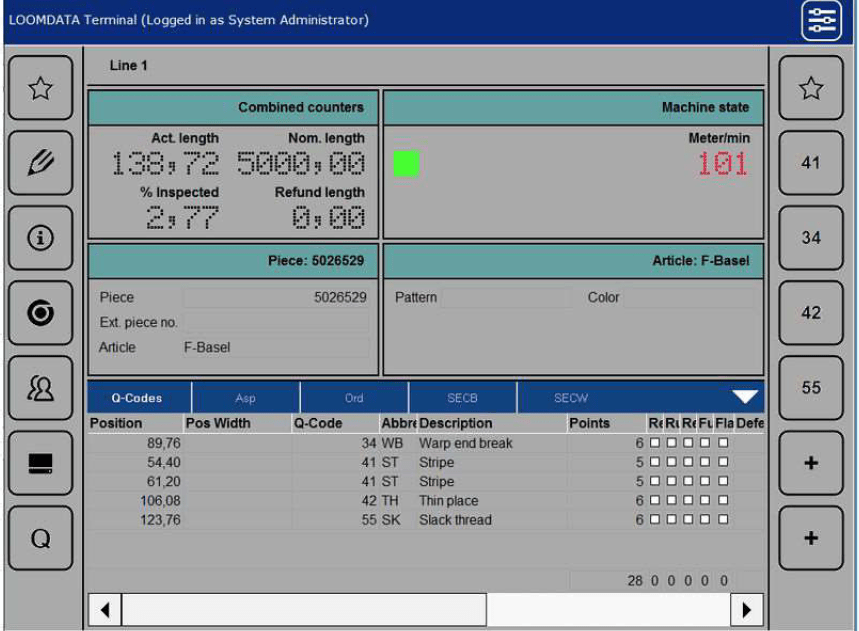

With LOOMDATA the fabric inspection can be done in two variants: the most comprehensive and efficient solution is using an industrial computer running MS Windows as an inspection terminal. Up to four pieces can be inspected in parallel and optionally the inspection table can be driven by keys. An alternative is using the LOOMDATA MS7 as an inspection terminal for work places with less high demand on flexibility and comfort.

Defects and Measurements

The measurements (for example the width, weight, and fabric characteristics) can be entered by the operator directly on the inspection table. The fabric defects are distinguished by their position and dimension, by repetition and severity etc.

Refunded Length

The PC measures the inspected length and calculates the refunded meters by taking into account the fabric defects entered by the inspector.

Extrapolated Number of Defects

Usually, the online quality inspection does not allow a 100% inspection of the fabric. Therefore the defects found on the inspected part of the fabric will be extrapolated to the whole fabric. This extrapolation can be enabled by type of defect to get a more accurate forecast for the quality.

Proposal for Quality

At the end of the inspection LOOMDATA proposes a quality index (1st choice, 2nd choice, waste etc) based on the inspected article, the customer and the number of defects found in the fabrics by the inspector. The inspector can either accept the proposal or enter a different quality index according to his valuation. Even during the inspection, real-time information is available like number of defects per 100 meters, number of points per 100 meters etc. All this information can help to define the final length of the pieces.

Cutting and Cut Optimization

According to the cutting order, the inspection table stops automatically when it reaches the length set for the roll. Then, the operator will decide whether to cut or to continue with production in case of defects on the fabric.

Online Quality Declarations

The inspector and/or the machine operator enters defects during the production of the fabrics directly on the weaving or knitting machine. This is called online or on-loom quality declaration and gives an immediate feedback to the production to fine-tune machine settings.

Critical Pieces

Based on the online quality declarations, the report shows critical pieces with serious quality problems based on defects or points per 100 meters and predefined tolerances. It shows also pieces that tend to get serious problems.