Base System

The Base System includes the basic hardware and software components of a LOOMDATA system. It is the platform for operating and extending our solution in your company.

- Proven: With more than 35 years of experience in production monitoring LOOMDATA is the most reliable system on the market today

- Comprehensive: The base system of LOOMDATA provides all the tools needed to monitor the processes of the modern manufacturing facility

- Expandable: LOOMDATA can grow as needed with optional modules for every department of your company

- Future-proof: thanks to our standard software, constant updates and professional support

- Connected: due to an efficient and flexible OpenSystem Interface

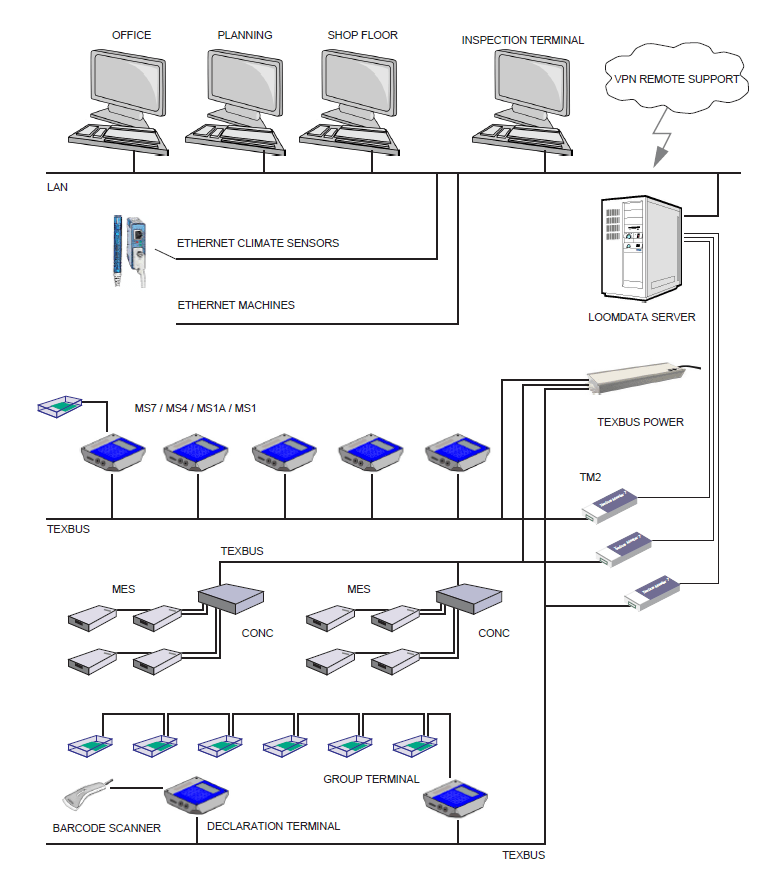

Extensive Connection Choices

LOOMDATA 4 offers a variety of choices for machine connections and communication possibilities. Modern machines can be connected using Ethernet or serial VDI, if available. Data can be collected from almost any type of machine using the flexible design of the LOOMDATA 4 machine stations. Production information can be detected either digitally or by analog signals. The human interface allows entries into the system by using machine station keyboards, RFID, barcode scanners, wireless portable data stations or by PC client terminals.

Event History and Statistics

Run and stop events as well as any personnel declarations are collected from every monitored machine. This highly accurate data allows analysis of machine and personnel performance. The reports are presented either numerically or graphically.

Shift and Long Term Reports

For performance comparisons, all data is collected and stored by individual shift. This allows the user to make different reports by:

- Machine, machine type or process

- Style

- Operator, Fixer, Supervisor etc.

- Yarn

- Test Group

- Plant or Room

- Time (trend reports)

- Order

All of these report types allow extensive filtering of the collected data and exception values are high- lighted if the values shown are out of limits.

For the analysis of longer-term data, reports are available by week, month or a user defined time frame.

Material Reports

In the material reports, the analysis of the data is related to produced items. This is the warp in weav- ing preparation and the piece in weaving, finishing and inspection.

All automatically and manually collected data is shown in material production maps and numerical reports:

- Stops

- Declared codes (Out of Production-Codes, Call Codes and Activity Codes)

- Quality Codes (Defects)

- Measurements

- Process Data

- Process step data (when and how the produc- tion has taken place)

The graphical tracking reports show a production data “Road Map” with all the various process steps that the item has been through. This allows a quick visual recognition of problems and their effect on the production and may allow many production problems to be eliminated.

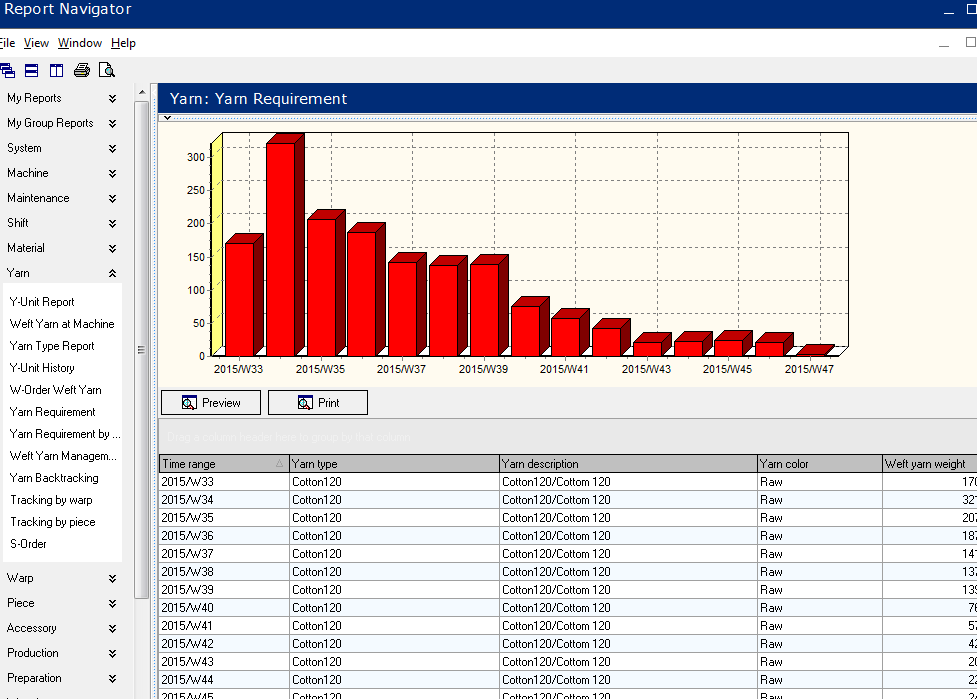

Report Navigator

The new Report Generator presents reports in a unique, consistent and easily understandable way. The reports can be easily modified to the needs of the user by changing groupings, sorting and the number of columns that are shown in a report. The modified views can be named and saved.Then the user can easily switch between the different views of any report.

Machine Layout

The new hierarchical Machine Layout is the dash- board of the fixer and supervisor. All machines are shown by a single symbol in one or more layouts. Each symbol shows the machine state and up to three production or assignment values. Problem machines or machines which are out of limits are shown in red to get the user’s attention.

The Machine Layout is the starting point for detailed analysis of machine and plant performance. All per- sonnel declarations can be done in the Machine Layout without having to travel to the machine.

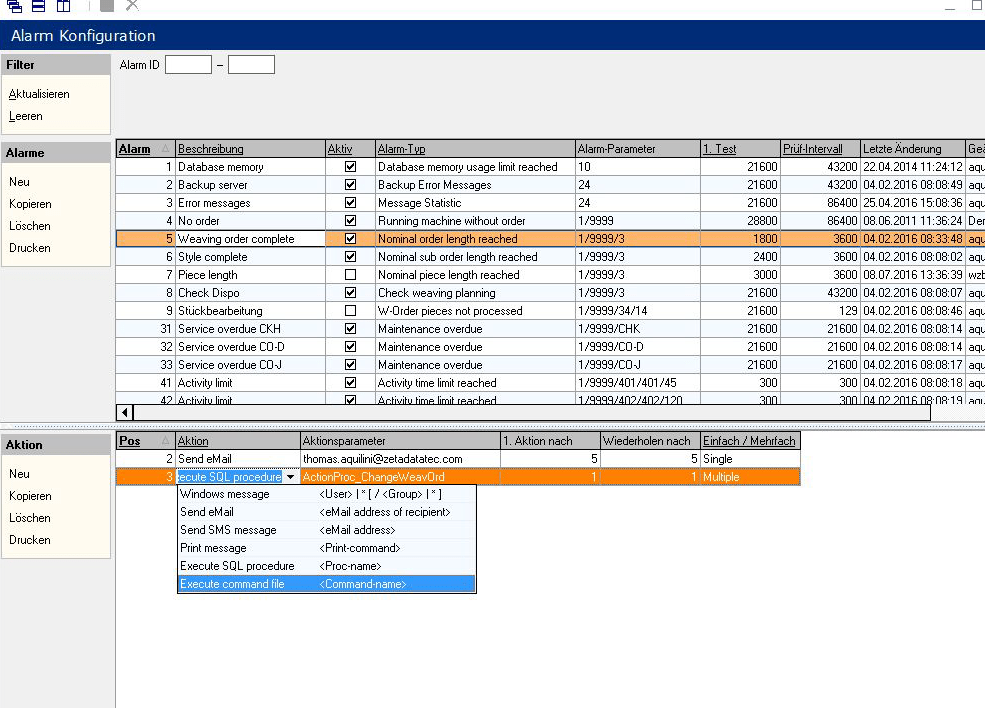

Alarm Server

The Alarm Server monitors various criteria like piece or order length reached, machine running without order, planning does not exist, data backup failed, etc. Additional criteria can be added easily according to your needs.

Flexible Alarming

In case of an alarm, various possibilities exist to get the operator’s attention:

- Sending a message to the PC screen of the user.

- Sending an E-mail to the user.

- Sending a SMS to the user (appropriate SMS service is required online).

- Printing a message on a printer.

- Activating an electrical output for signaling or controlling a device.

- Invoking a command on the LOOMDATA server.

- Invoking a procedure on the LOOMDATA da- tabase.

In fact, the last two possibilities have no limitation to any sort of action.

Detection of Planning Bottlenecks and Production Breakdowns

Delayed or forgotten changes on the machines can be detected early to allow the appropriate reaction in reasonable amount of time. So you can make sure that planning and production matches all the time.

Targeted Staff Training

You will benefit from our training opportunities by being able to reduce the introduction phase of new functions or new employees and to take full advan- tage of our software.

OpenSystem

Included in the base system functionality you will find the sophisticated OpenSystem Interface. This system allows you to access the LOOMDATA 4 data with standardized tools and protocols. We will be happy to assist you in meeting your system integra- tion needs by building an interface for you or by pro- viding training so that you can build your own inter- faces. Interfaces to third party systems of textile and non- textile computer systems are readily available through Zeta Datatec or other suppliers.