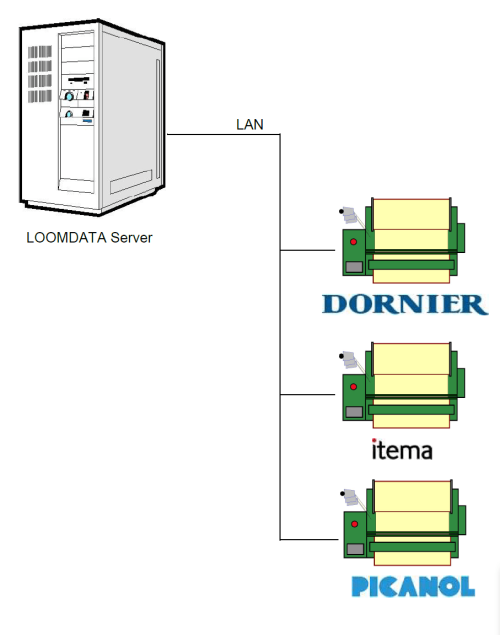

Weaving machines with an Ethernet port can directly be connected with the LOOMDATA server via LAN (Local Area Network) for data exchange.

The weaving machines are directly connected with the LOOMDATA server via LAN. It communicates with the machines and receives production data as well as user inputs by the TCP/IP protocol.

The Ethernet driver is available for new weaving machines of the following manufacturers:

The following declarations can directly be entered at the control panel of the machine.

If uniform operation is important, one MS7 per machine can be used as declaration terminal for user inputs.

jasdf![]() knda.

knda.