Option Yarn Planning

From storage of yarn in the warehouse to the last phase of fabric processing, yarn planning and management is the basis for profitable manufacturing without any delays.

- Optimizing: reduces stock level

- Efficient: prevents production loss due to waiting times

- Real time: all stock values are accurate at the very moment. LOOMDATA knows the requirements and consumption

- Reports: freely definable with SAP Crystal Reports

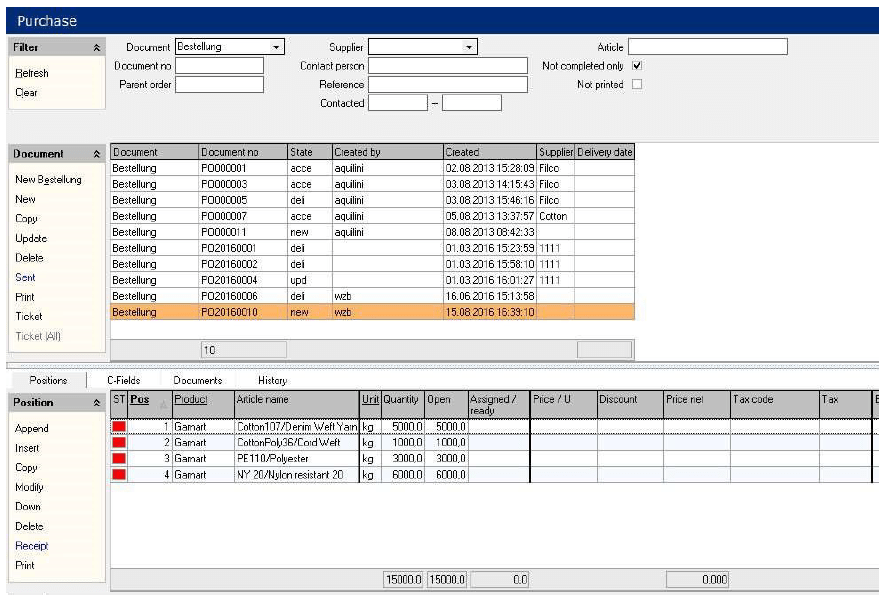

Management of Yarn Units

One yarn unit managed by LOOMDATA is usually is a pallet or box with the same yarns from the same lot. These yarn units may be reserved for specific orders. LOOMDATA can already predict the quantity that will be used and re-enter the stores.

Reservation of Warp Yarn

With the planning options available in LOOMDATA the required quantities of warp yarn are pre-determined according to the existing orders. Thanks to optimization the creel change times are reduced to a minimum.

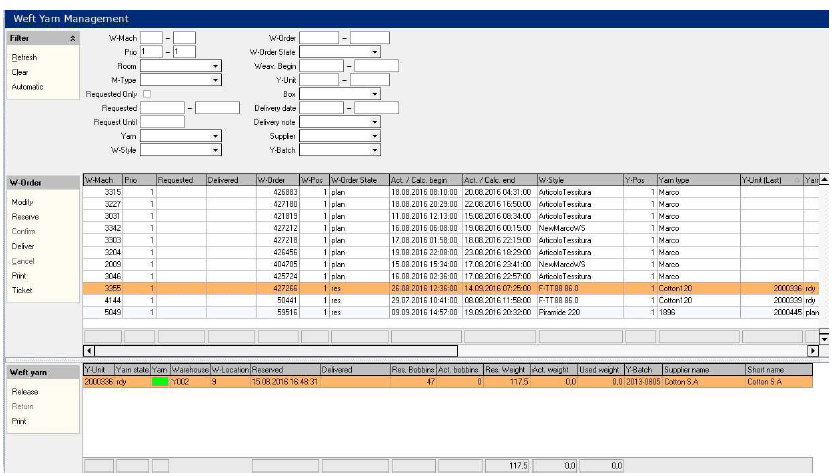

Reservation of Weft Yarn

Distribution of Weft Yarn

The distribution of the weft yarn takes place on the base of bobbins. Where the system generates a list of requirements based on of yarn calls on the weaving machines or created on the basis of the calculated consumption. The Planner or delivery person can now specify how much bobbins from which yarn unit to the machine to deliver. The actual distribution is confirmed either on the PC, on the machine stations or mobile terminals. In the same way return to stock of surplus bobbins is handled.

Yarn Inventory

LOOMDATA constantly maintains the remaining stock levels and checks the quantities at the loom. The LOOMDATA inventory system simplifies this operation considerably.