Weaving Planning

The comprehensive solution for greige fabrics, fancy fabrics, technical fabrics, as well as terry, narrow and jacquard weavers.

- Established: with more than 35 years of experience

- Flexible: can be applied to all types of textile manufacturing

- Robust: for small and large weaving mills

- Integrated: in weaving preparation, inspection and finishing

- Delivery reliability: by forecasts for orders, resources and material requirements

Weaving Order

The Weaving Order is the core of Weaving Planning in LOOMDATA. No order is too complex to be handled. The following production features are supported:

- Multiple production lines

- Multiple warps, organized in feeding lines and etages (pile warps)

- Sequence of different styles on the same warp(s)

- Planned piece cuts with the same or different nominal lengths

Planning assignments are checked to determine if the style(s) is (are) allowed to be woven on the selected machine and whether the weaving width of the machine has been exceeded.

The basic data contains information about the styles that is required to make planning accurate and easy:

- Standard piece length and pick density

- Warp type with contraction and standard warp length

- Weft yarns with appropriate density in the fabric

Unassigned and Assigned Orders

Thanks to the real time data collected by LOOMDATA, the planning department has an accurate overview of the situation in the weaving room. So they are able to easily decide which machine is the best to be assigned to the respective weaving order. With this type of information most customers choose to plan the production in LOOMDATA over other in plant systems.

Manufacturing Order: Knowing What Will Come When!

The Manufacturing Order is the preferred interface to your order administration. Thanks to the customer based order tracking, the delivery dates and amounts are no longer uncertain. The manufacturing order extends the prediction to the finishing department as well.

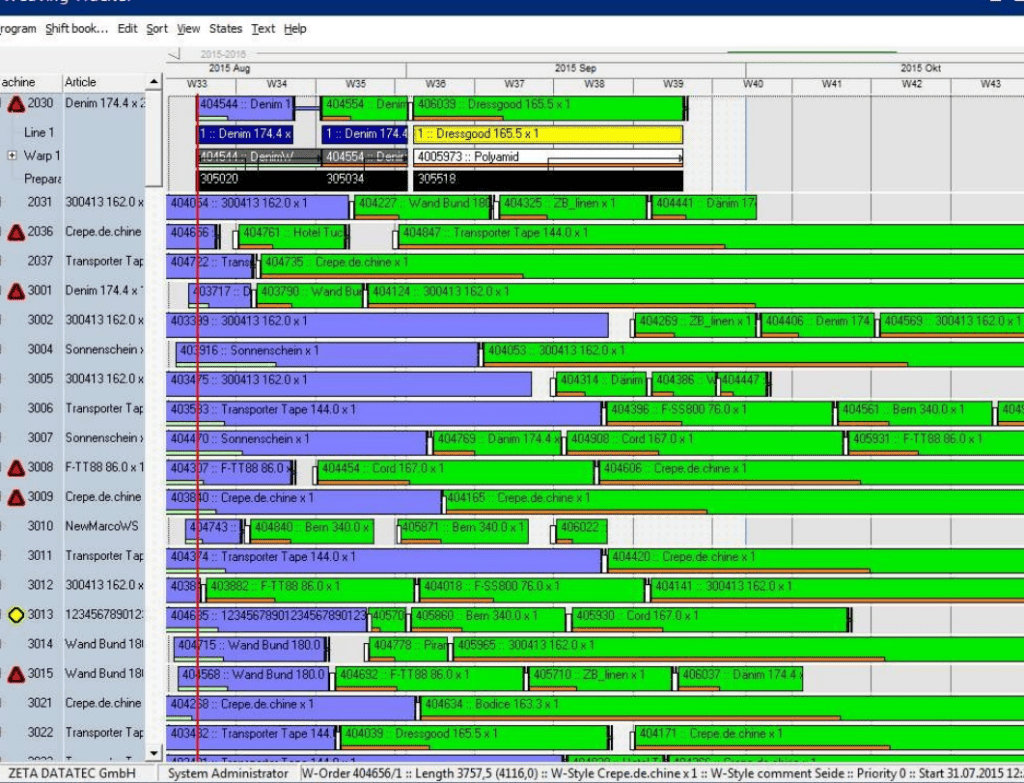

Planner

The Weaving Tracker shows completed, running and planned weaving orders in a powerful and flexible presentation. Various views show planned style changes, planned warp changes, setup information, order information and much more.

The planner is constantly updated with the latest information directly from the looms. The planer can move weaving orders from one machine to another very simply by just dragging the order to the new machine and position.

Order Declarations at the Looms

Warp Changes

Manage and monitor the warp changes performed by the warp change personnel. The start time and duration of each step in the warp change process can be recorded using the LOOMDATA Machine Station.