Weaving Preparation Planning

This software options allows continuous planning of weaving preparation and weaving, as well as tracing of material from yarn to warp.

- Integrated: consistent solution for all stages of the textile flat production (weaving preparation, weaving, raw material inspection, finishing and finished goods inspection)

- Optimized: sequential planning for all and especially bottleneck machines

- Just in time: forecasts by warp requirement reports

- Sustainable: evaluations referring to warps / preparation orders

- Accurate: discrepancies of warp lengths from planned values are detected early

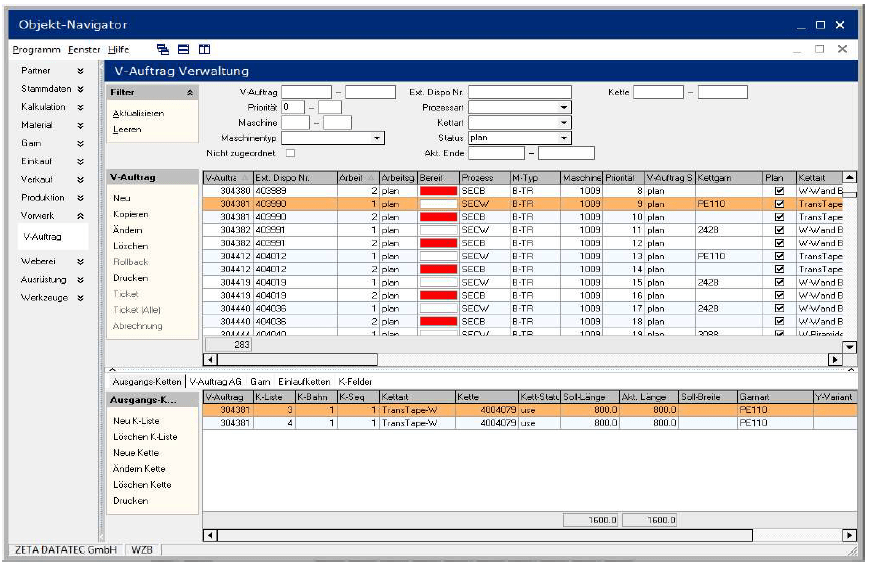

Preparation Order

- Warping / Beaming: both warping and beaming are recorded and analyzed correctly as individual processes. Both the re-beaming of warps as well as the processes of warping / beaming of the same yarn are supported in LOOMDATA.

- Sectional Beaming: define the composition of the sectional warp and monitor its production. If necessary, the single sections can be managed as single or partial warps.

- Drawing-in: connect the LOOMDATA system to automatic, semi-automatic or manual drawing-in workstations.

- Sizing, Assembling

- Rope Dyeing

Kettlager und Kettverwaltung

Warp inventory is integrated into the standard LOOMDATA system. The warps and section beams can be stored, removed from the warehouse and, above all, can be located easily. Searching for warps can be a thing of the past.

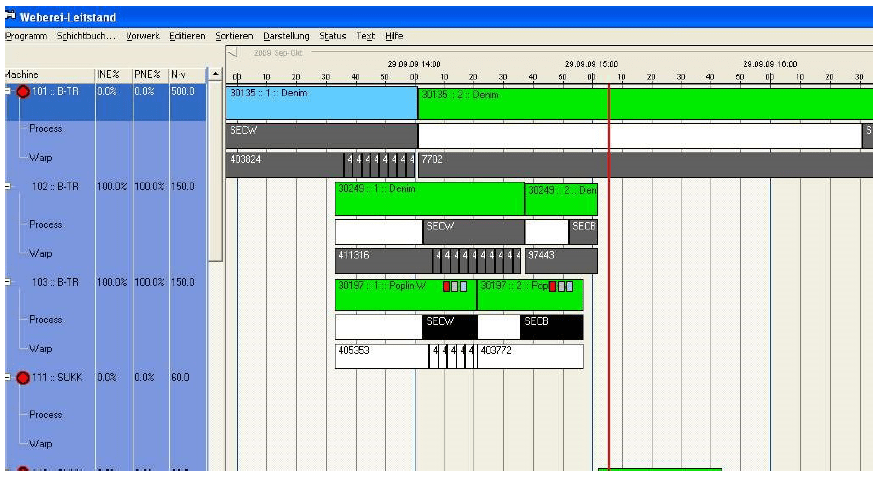

Preparation Tracker

The planning of your preparation machines will be displayed graphically in the Preparation Tracker. Bottlenecks and delays can be easily recognized and avoided.

Warp Warehouse and Management

The LOOMDATA machine stations allow data collection of work processes via VDI interface or directly via their own sensors in future. In the graphical tracker it is possible to clearly see the effects of changes in the manufacturing process on the fabric.